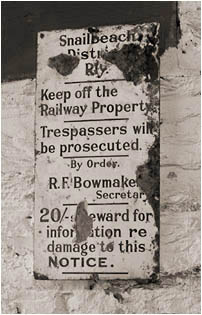

Snailbeach Lead Mine |

||

17th Century WorkingsThe earliest known recorded evidence of mining at Snailbeach dates from 1676, when a group from Derbyshire took out a lease to work the area. This lease was renewed ten years later in 1686, but it is not known how successful their efforts were.

18th Century Workings The start of an almost continuous 200 years of working on the Snailbeach site began in 1761 when a five year lease was taken out by a Mr. Thomas Powys, he renewed the lease in 1766 for a further 6 years. A gap of 10 years seems to exist after the previous lease expired before Mr. Thomas Lovett took out a lease for 21 years in 1782, presumably the mine had already by this time proven itself profitable enough to justify such a long commitment. The following year a Deed Of Partnership was signed with seven others to form the 'Snailbeach Company'. A year later, in 1783, Thomas Lovett opened a smelt house opposite his coal mine in Pontesford, this allowed ore from Snailbeach to be taken to Pontesford for smelting, before carrying coal back up to Snailbeach to fuel the boilers at the mine. The start of an almost continuous 200 years of working on the Snailbeach site began in 1761 when a five year lease was taken out by a Mr. Thomas Powys, he renewed the lease in 1766 for a further 6 years. A gap of 10 years seems to exist after the previous lease expired before Mr. Thomas Lovett took out a lease for 21 years in 1782, presumably the mine had already by this time proven itself profitable enough to justify such a long commitment. The following year a Deed Of Partnership was signed with seven others to form the 'Snailbeach Company'. A year later, in 1783, Thomas Lovett opened a smelt house opposite his coal mine in Pontesford, this allowed ore from Snailbeach to be taken to Pontesford for smelting, before carrying coal back up to Snailbeach to fuel the boilers at the mine.Snailbeach continued to prosper and by 1797 the workings had reached 180 yards below the collar of "George's Shaft" (called "Old Shaft" at the time). During the same year work on a drainage tunnel had almost finished, the adit runs from the bottom of the Hope Valley at Wagbeach up to the mine, meeting the workings at the 112 yard level. A water wheel was installed which drove rods along the adit to operate pumps at the bottom of Old Shaft, these lifted the water up to the 112 yard level from where it could drain out naturally. 19th Century Workings An idea of the profitability of the mine up to 1820 can be gauged by the £43,000 worth of royalties paid to the landowner, the Marquis of Bath. A few years later, in 1827, a report was commissioned in which the author wrote that the mine was, "rich beyond most things I have been acquainted with in mining". The peak of the mine's production was reached in the early 1850's when it was recorded that 3,500 tons of lead was being produced annually, at this time 500 men were being employed at the mine. In 1857 Thomas Lovett was replaced as agent and a major refurbishment and investment in the mine's infrastructure began. The aging waterwheel used to pump the mine workings was replaced with a 61" Cornish pumping engine located on Lordshill, and a reduction of the workforce in 1859 combined with increased working hours initialy caused unrest amoungst the workforce, until it was pointed out they were already being paid more than miners elsewhere. In 1863 a new Smelt House was built about a mile from the mine with a tramway connecting the two, a flue was constructed to take the smelter fumes to a chimney located above the mine on Lordshill. A substantial new powder house was constructed and for the first time the mine started to produce zinc and barytes alongside lead ore. An idea of the profitability of the mine up to 1820 can be gauged by the £43,000 worth of royalties paid to the landowner, the Marquis of Bath. A few years later, in 1827, a report was commissioned in which the author wrote that the mine was, "rich beyond most things I have been acquainted with in mining". The peak of the mine's production was reached in the early 1850's when it was recorded that 3,500 tons of lead was being produced annually, at this time 500 men were being employed at the mine. In 1857 Thomas Lovett was replaced as agent and a major refurbishment and investment in the mine's infrastructure began. The aging waterwheel used to pump the mine workings was replaced with a 61" Cornish pumping engine located on Lordshill, and a reduction of the workforce in 1859 combined with increased working hours initialy caused unrest amoungst the workforce, until it was pointed out they were already being paid more than miners elsewhere. In 1863 a new Smelt House was built about a mile from the mine with a tramway connecting the two, a flue was constructed to take the smelter fumes to a chimney located above the mine on Lordshill. A substantial new powder house was constructed and for the first time the mine started to produce zinc and barytes alongside lead ore.In 1870 the post of agent changed hands again and another major refurbishment of facilities took place, over the next couple of years a new dressing plant was installed as were steam powered crushers, George's shaft was deepened, and a winding engine installed. The previous shortages of water at the mine led to the construction of a large reservoir in 1872, this provided a constant source of water that was a necessary part of the ore processing and sorting process. Nine years later a compressor house furnished with 2 Siemens & Edwards compressors was completed to drive the compressed air tools that were used in the mine.

Unfortunately the market for lead had reduced due to cheaper sources being imported from overseas, in 1884 the company recorded it's first loss. After liquidating and then reconstituting itself the company continued operations on a smaller scale, but the falling price of lead meant by 1895 it was no longer possible to sustain the nearby smelt house, which closed. At around the same time Snailbeach reached it's deepest when the 552 yard level was excavated, these became the deepest workings in the area, although by now the company was reliant more on zinc ore and barytes than lead ore itself.

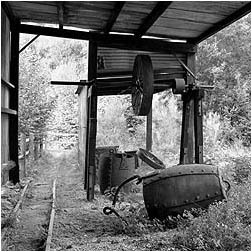

20th Century Workings At the turn of the 20th century the workforce at Snailbeach had dropped to 150, a fraction of it's former workforce of 500 just 50 years earlier. In 1900 the Halvens Company was formed (Halvens being a Cornish word for waste) which took out a lease to rework the mine spoil tips, an engine house was constructed on the tips around this time to drive their machinery. In 1905 just 200 tons were produced by the mine, but five years later the output reached a final peak of 1,000 tons before the Snailbeach Company ceased trading in 1911, the pumps being brought to rest in January of that year. Mining on the site continued even after the end of the Snailbeach Company as the Halvens Company took over the upper levels of the mine and continued operations around Black Tom shaft. In 1913 the company erected a new head frame over George's Shaft with a single winding wheel, this replaced the earlier head frame that used twin wheels. By the late 1920's production of barytes had fallen and in 1930 the Halvens Company ceased trading. Although the Halvens Company had gone, elsewhere on the site mining still continued in a small way. With it's operations centred around Perkins Level and the upper workings of the mine, the Snailbeach Barytes Company supplied the Halvens Company's former customers, and underground mining continued up until 1950 when their efforts became more surface orientated, although underground mining didn't finally finish until 1955. After this date the Snailbeach Barytes Company continued further processing of the spoil tips, in 1965 it is reported that the company produced 8 tons of barytes and 1,020 tons of gravel. During the 1970's the company was listed as producers of hardcore.

Reprocessing at Snailbeach finally drew to an end in the mid 1980's, when the next stage of the site's history began. In 1985 the Halven's Engine house, built in 1900, was demolished. When the County Council became aware of this development they took action which prevented the demolition of further buildings. It is suggested that the company was informed by the council that they were to clear the site before finally abandoning the area, the council were apparently referring to the modern reprocessing equipment and caravans used as offices, rather than the earlier mining remains, but the misunderstanding saw the demolition of one building and the intention to clear the remainder of the site. Reprocessing at Snailbeach finally drew to an end in the mid 1980's, when the next stage of the site's history began. In 1985 the Halven's Engine house, built in 1900, was demolished. When the County Council became aware of this development they took action which prevented the demolition of further buildings. It is suggested that the company was informed by the council that they were to clear the site before finally abandoning the area, the council were apparently referring to the modern reprocessing equipment and caravans used as offices, rather than the earlier mining remains, but the misunderstanding saw the demolition of one building and the intention to clear the remainder of the site.The mine was left to slowly return to nature until the early 1990's, when the Council took action to stabilise the many underground workings situated just below the surface. At the top of Lordshill the workings had actually collapsed and for many years the road was carried on a temporary bridge. In 1991 the locomotive shed became the first building to be conserved, and in 1993/4 the upper workings and other buildings were stabilised, open shafts were capped and the once distinctive white spoil tips were landscaped away, to be hidden under membranes and top soil.

|

||

| All photographs are the work and copyright of Ian Cooper. | ||